Most of the global players and many small and medium-sized manufacturers of implants, instruments and medical devices rely on us when installing a UDI-compliant marking process. Our commitment to total customer satisfaction as well as worldwide service ensure your sustainable success.

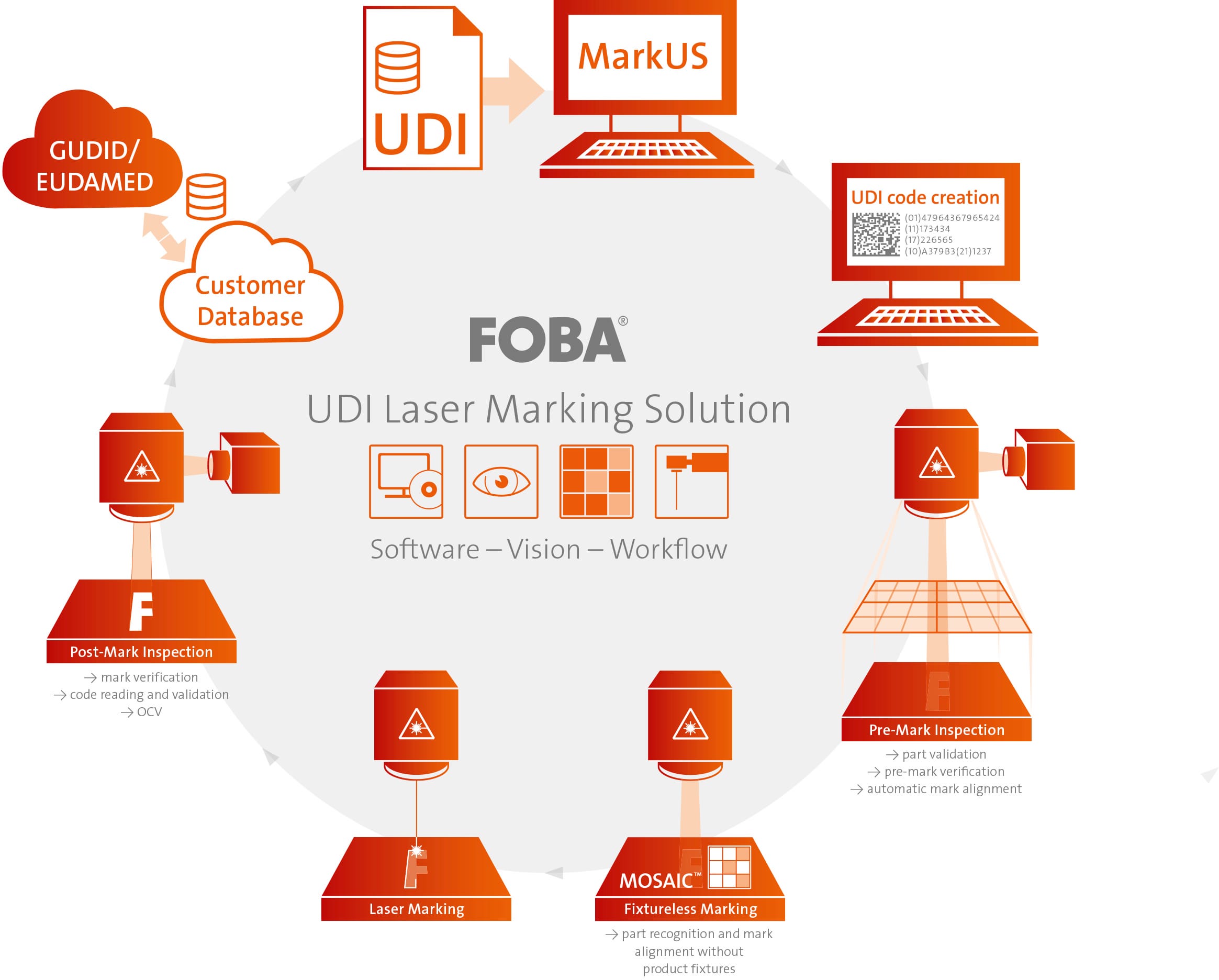

UDI Compliance

- Support for all regulatorily (FDA, MDR) mandated UDI code formats (bar codes, data matrix codes, etc.)

- Creation of permanent, resilient, high-contrast UDI marks that ensure full readability even after numerous cleaning cycles and throughout the entire product life cycle

Code Format Reliability

- HIBC Approved Solution Provider and GS1 Solution Partner

- Support for most commonly used UDI code designs GS1 and HIBC

- Code-conformity acc. to the AIM DPM standard (ISO/IEC 15415)

High-Quality Marking

- Universally applicable laser systems mark the complete variety of medical materials

- Including 4301 Stainless, Titanium, PEEK, POM, PPSU, etc.

- Multiple wavelengths (fiber, CO2, UV) for every material request

- Creation of durable, counterfeit-safe, highly precise sharp-contour characters, machine-readable codes and other formats

- Autoclavable black-marking for metal medical devices with Y.0201

- High-contrast marking of sensitive plastics with V.0020-UV

- Creation of codes that are resistant to sterilization and cleaning processes

Vision Inspection, Code Validation

- Patented, laser built-in through-the-lens vision system IMP (Intelligent Mark Positioning)

- 4 pre-mounted, fully software-controllable lightbars allowing for even illumination and reducing unwanted hot spot reflections

- Pre- and post-mark inspection ensures drastic scrap reduction:

- Part validation and pre-mark verification prior to marking

- Automatic mark alignment with IMP

- Fixtureless marking with patent-pending MOSAIC™ feature

- Mark verification, code validation and OCV (Optical Character Verification) after marking

Closed-Loop Marking Process

- Vision-guided Holistic Enhanced Laser Process (HELP)

- Part and mark validation with pre- and post-mark the inspection ensures drastic scrap reduction

- High-precision automatic mark alignment

- Only the correct marks are applied to the correct parts on the right position

- Mark verification and code validation incl. OCV (Optical Character Verification) after marking directly in the marking laser machine

Fixtureless Marking

- FOBA MOSAIC™ – full-field scanning

- Automated mark alignment on parts that are loosely placed within the marking field

- Expensive part fixtures are no longer needed

- Significant cost savings in production and equipment validation

- Ease of Use and Integration

- Advanced Operator Plugin (AOP) ensures a safe and error-free UDI marking process that helps improve production efficiency and facilitate laser marking for users with any skills

- AOP captures inspection results and provides "Documented Evidence of a Stable Process"

- Built-in software/ERP interfaces (Majesty, SAP, etc.)

- Easy adaption to production and data processing environments Technological Expertise

- 35 years of excellence in the laser marking business

- Combined experience in medical part marking unparalleled

- Continuous R&D in vision-assisted laser marking

- Close insights into the requirements of medical manufacturers

- Intense cooperation with notified bodies and medical authorities

Worldwide Services

- Acceptance Packages incl.

- Factory Acceptance Test FAT and Site Acceptance Test SAT

- Process Capability Testing (CpK)

- Machine Qualification

- Customer-specific end test

- Customized mechanical and software engineering in order to meet customer-specific requirements and challenges

- Dedicated lifecycle services incl.

- Service Care Packages (SCP), IQ, OQ, PQ, MQ

- Remote diagnostics & system monitoring

- 24/7 hotline support (depends on SCP)

- Dedicated global service tech network

- Global spare parts stocks

- Local consignment stocks

- Spare parts availability: min. guaranteed

- 5 years and up to 10 years on demand

- On-site customer training

- IoT data with FOBA Remote Service (FRS)

- Global application development and on-site support

- Up to 5 years warranty with SCP