A special grid structure made of Ti6Al4V was deposited on a bar using additive manufacturing (AM). There were small metallic droplets on the surface. Fatigue tests resulted in early failures because of the higher hardness of the AM-structures and the interface compared to the bulk material.

Introduction

In recent years, additive manufacturing (AM) has developed into a promising manufacturing technology with revolutionary possibilities such as “complexity for free”. In contrast, the physical properties of these components are often neither known nor assessable. This entails new risks and challenges with regard to the quality and reliability of such products, especially for applications in medical technology.

Material & Methods

Special grid structures made of the titanium alloy Ti6Al4V were deposited on bars made of the same alloy using laser metal deposition (1.9 mm high structure on 60 x 10 x 5 mm bar, device „OFH“ at Fraunhofer Institute for Laser Technology ILT, Aachen, D). Surface properties of these structures were investigated using confocal microscopy and scanning electron microscopy (SEM). The fatigue resistance was subsequently investigated using a 4-point bending test (270 - 637 MPa, 10 Hz). Finally, a fracture analysis was performed on the tested samples.

Results

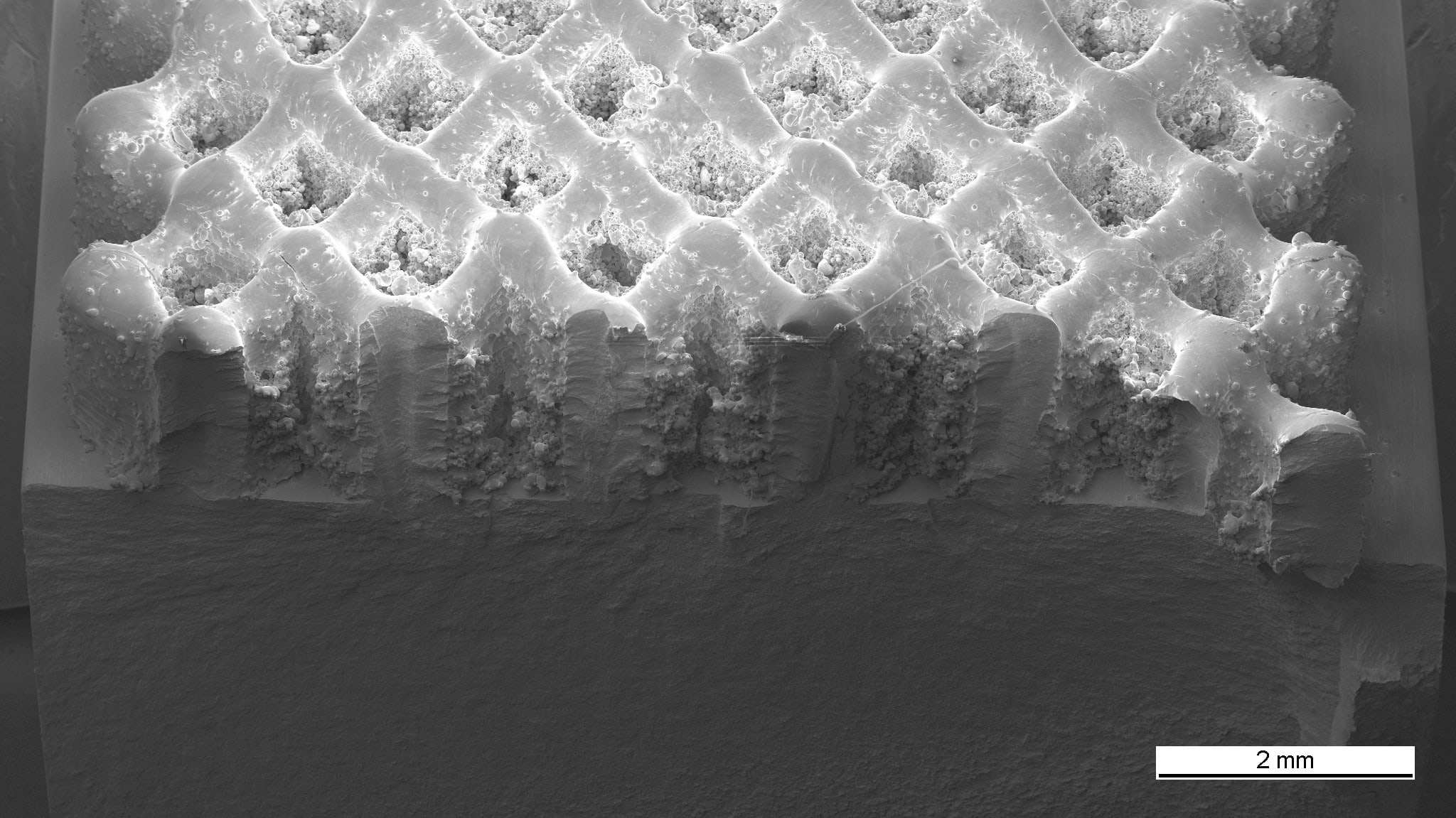

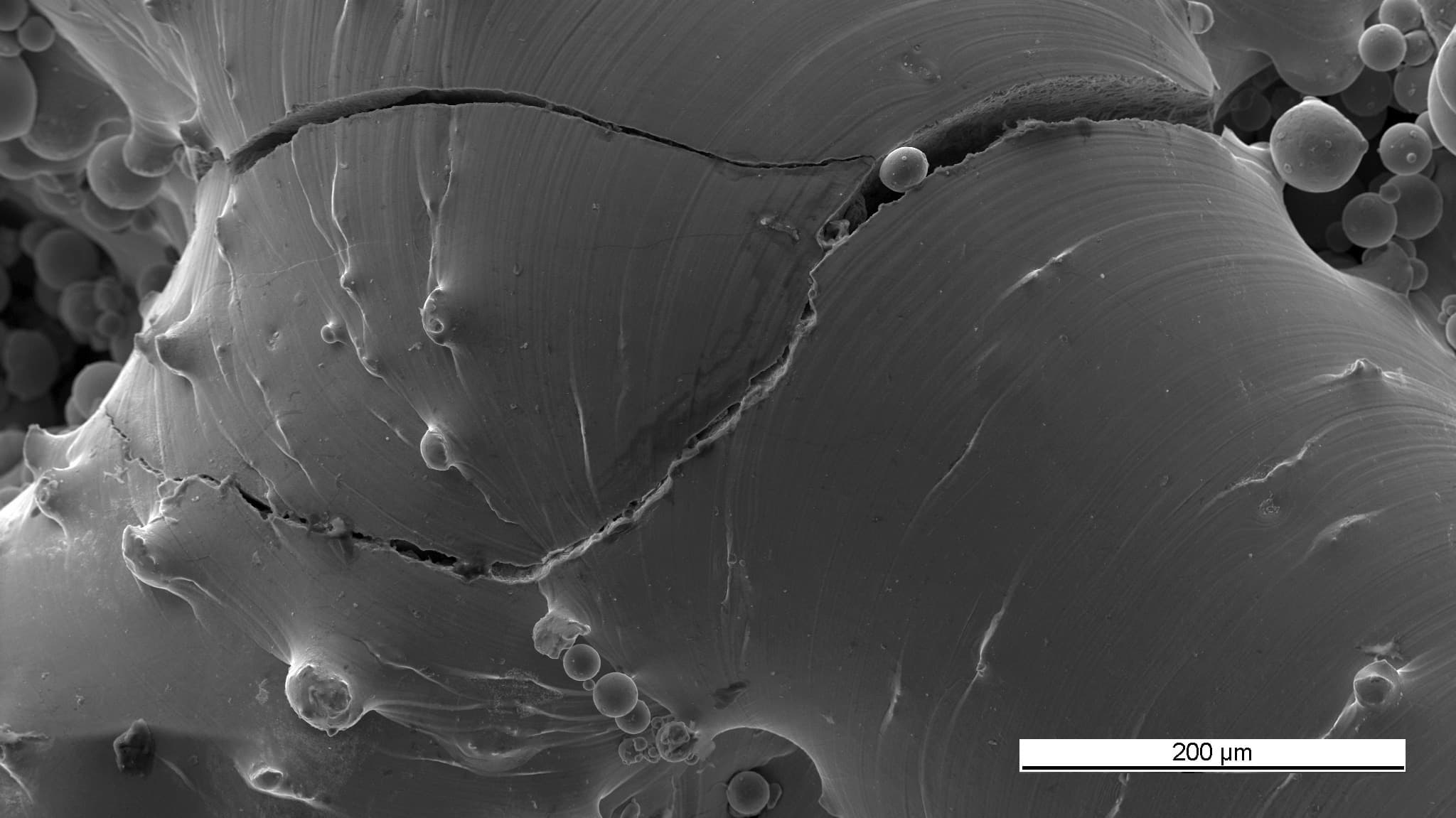

The surface analysis showed small metallic droplets on the surface of the AM-structures. The roughness Ra of the structures ranged from 0.11 to 1.2 µm. There was an early failure of the bars with the AM-structures in the 4-point bending test (< 300'000 cycles at 270 MPa vs. > 700'000 cycles at 600 MPa for Ti-bars w/o structure). The SEM-investigation showed multiple crack initiation within the AM-structure (Figs. 1 & 2).

The metallographic examination of the broken samples showed additional secondary cracks that started at the interface (Fig. 3). The microstructure of the AM-structure and of the heat affected zone at the interface was dendritic, while the bar exhibited small grains. The AM-structures were harder than the bulk (389 ± 2 vs. 322 ± 10 HV0.5). This was related to a higher oxygen content in the AM-structure.

Discussion & Conclusions

The reason for the failure was the higher hardness due to a higher oxygen content of the AM-structures compared to the bulk material. Thus the upper part was more brittle than the bulk. This led to cracks in the AM-structure and at the interface, and finally to the early failure of the components due to the cyclic bending stress and notch sensitivity.

This example shows that application specific testing and analysis can be crucial for product failure prevention.