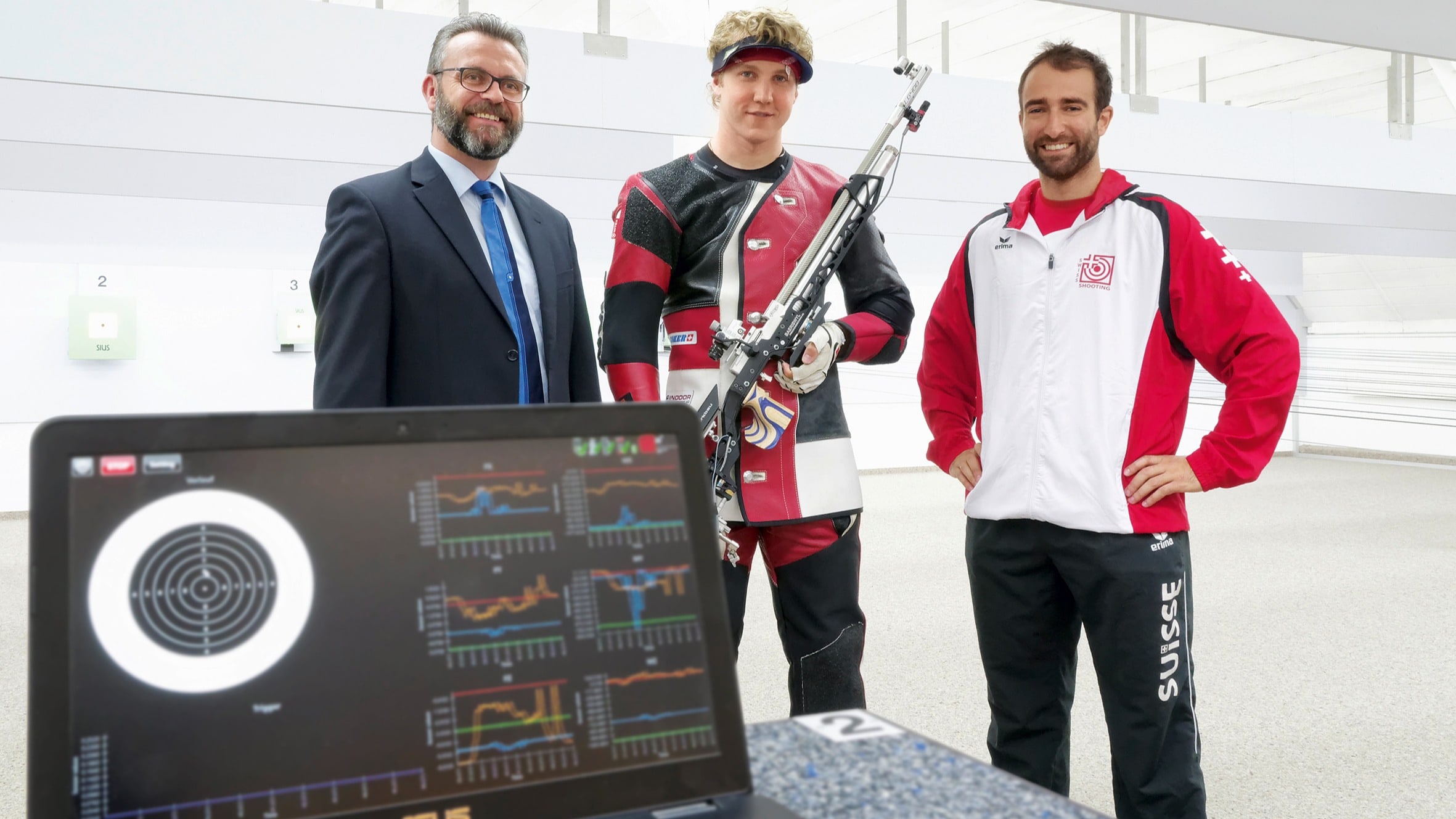

Researchers at the University of Bern use highly sensitive force-torque sensors from robotics to train Swiss squad shooters. What has already led to valuable findings for the perfect shot in top-class sport is now to be used increasingly in medicine and rehabilitation technology.

For minutes, sometimes even for hours, the Swiss Olympic marksman Jan Lochbihler remains stoically calm during training, concentrating solely on his breath and on the goal, which is barely visible to the naked eye. With maximum body control, the well-trained athlete searches for the decisive moment until he pulls the trigger motionless - and hits.

Every pulse-beat of the carotid artery, even the slightest restlessness that influences the position or position of the air pressure weapon, is continuously recorded on the control monitor. The goal is the perfect shot. Over and over again.

Technological bond in mechanical engineering

"The fundamental question of the project was how to optimize a precision sport such as sports shooting further," explains project manager Dr. Ralf Kredel, a researcher at the Institute of Sports Science at the University of Bern.

The athletes at the shooting range of the Swiss Shooting Association SSV in Biel are very enthusiastic about the use of force-torque sensors. "We use the sensor system to analyze all force values in the x, y and z directions as well as the torques," reports Dino Tartaruga, who is responsible for performance diagnostics within the SSV.

"We were able to see that Jan's scattering of the force value Fx at the shoulder is significantly lower with good shots than with bad ones," explains the sports scientist. "Conversely, this means that the shooter must pay more attention to his shoulder. Now the sensors show where the movement comes from," emphasizes the trainer.

Light sensors with high resolution and compact dimensions

For cost reasons, the company initially tried to design sensors on its own in cooperation with another manufacturer. However, the sensors had neither the measuring accuracy nor the stability of the high-resolution series models used today.

The main requirements were high reliability, reliability in the measurement results, high precision, robustness, low weight, and low overall height. All these criteria are met by the sensor series of the competence leader for gripping systems and clamping technology SCHUNK from Lauffen am Neckar.

While conventional force-torque sensors work with foil measuring strips, the FT sensors from SCHUNK are all equipped with silicon strain gauges. These provide a signal 75 times stronger than conventional sensor solutions.

They enable decentralized intelligence in the individual task and are suitable for monitoring process parameters, for decentralized quality assurance and for documenting quality criteria.

Basic research in robotic surgery or rehabilitation

The University of Bern is currently using highly sensitive force-torque sensors for basic research in the field of rehabilitation applications or robotic surgery.

Because what has already been successfully applied in competitive sports can be used in robotic surgery to promise people a faster recovery. A further area of application is rehabilitation to check whether exercises are performed correctly. Or to reliably measure the effectiveness of therapy.