Surface structure and roughness play an important role in a variety of applications. In dental and orthopaedic implants, for example, the microstructure is decisive for the ingrowth of the bone. Learn how to reliably measure roughness and topography.

In artificial joint replacements, for example, the roughness of articulating surfaces strongly influences the wear which is generated in these devices. In the case of dental and orthopedic implants, the material and its surface structure particularly determine bone growth and therefore its fixation to bone.

The exact measurement of roughness and surface structure

At the RMS Foundation, we use a modern, optical 3D-measuring device to measure the surface structure and roughness on many kinds of samples. The S neox from Sensofar allows measurements in different modes: interferometry (both phase shift and white light interferometry), confocal microscopy, and focus variation. With interferometry – combined with a piezo drive and active vibration control – depth-resolutions in the sub-nanometre range are possible. Rough samples can be investigated using confocal microscopy and the contour of a sample can quickly be assessed with focus variation. Very large samples can be analyzed too, thanks to a one-meter high column for the sensor head.

Determine resolutions down to the nanometer range

If the lateral resolution of optical systems is not sufficient, then the topography can be assessed by scanning electron microscopy (SEM). Pictures of a surface are acquired at two different tilting angles and thus the topography can be determined semi-quantitatively. Herewith lateral resolutions down to few nanometres can be achieved. Besides the surface roughness parameters, the more common profile roughness values can be determined by extracting and evaluating multiple profiles from the measured topographies. Several single topographies are usually stitched together to obtain a larger topography, based on which the roughness values can be determined according to ISO standard 4288:1996. This can be performed for highly polished surfaces as well as for rough samples.

Application on an artificial joint

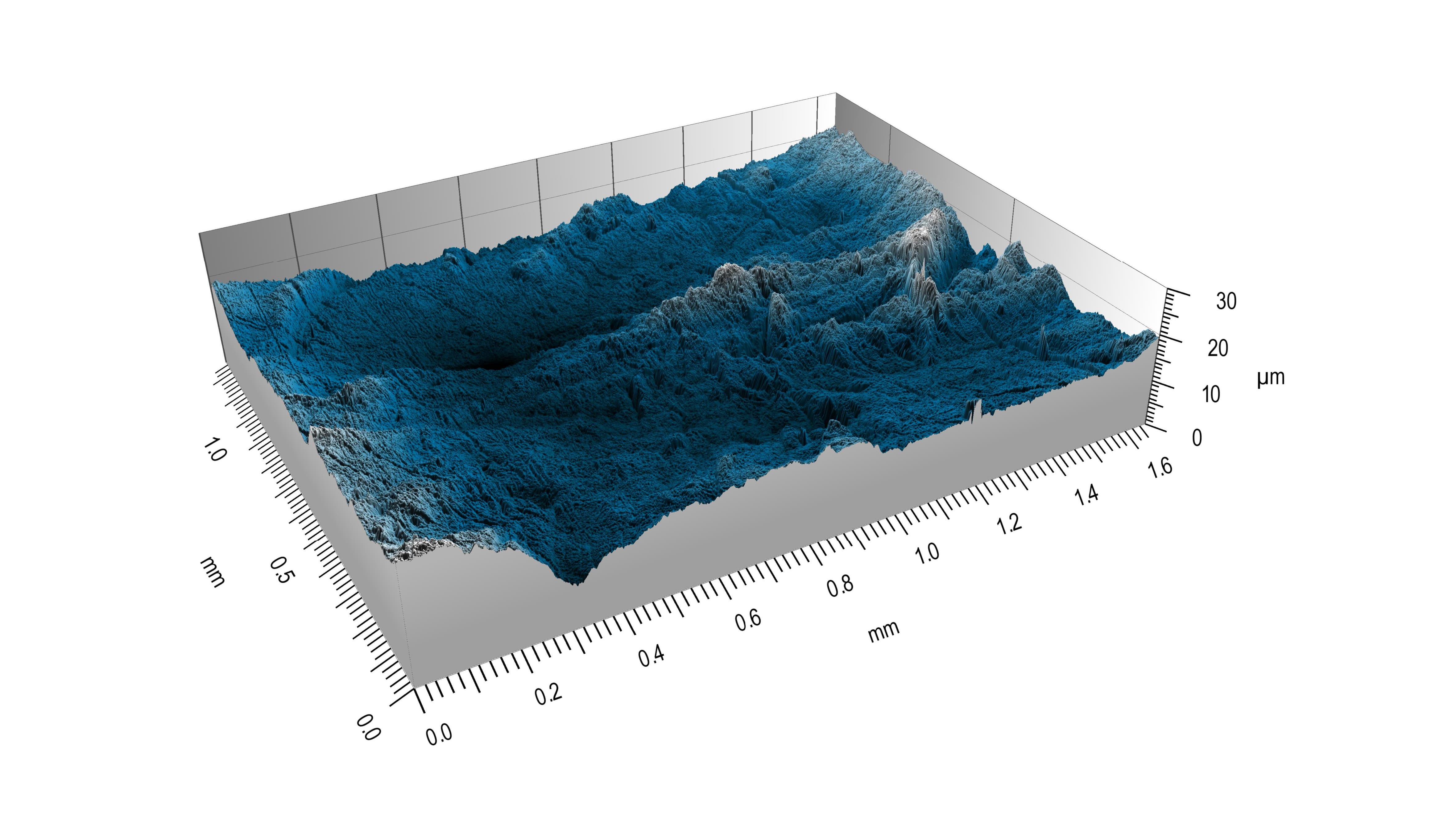

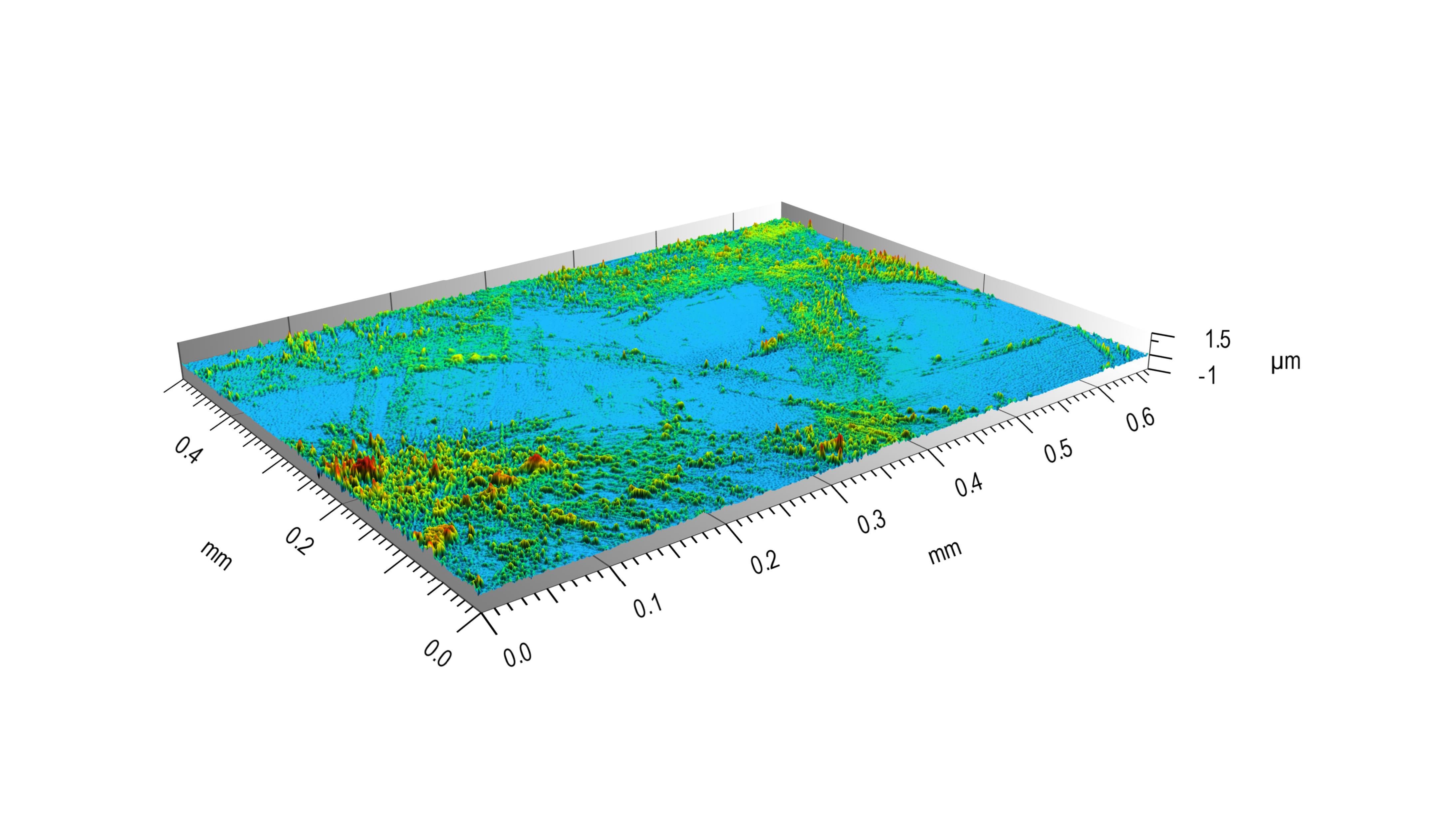

The S neox is used for various projects, both for testing and research. For example, an artificial ceramic-on-polymer joint was investigated, which was heavily damaged in vivo by third-body wear caused by metallic particles, which entered into the articulation. The surfaces were documented using white light interferometry. It was shown that the softer polymer part was heavily scratched (Figure 1) while there was material transferred onto the ceramic part (Figure 2). This material caused a higher roughness which in turn led to more abrasion of the polymer part.

Optical roughness measurement

Device

S neox from Sensofar

Measuring modes

• Interferometry (Phase shift and white light interferometry)

• Confocal microscopy

• Focus variation

Sample requirements

Solid samples

Dimension < 60 x 60 x 60 cm

Weight < 10 kg

Reflectivity 0.05 % to 100 %

Height difference < 40 mm

Lateral movement < 114 x 75 mm

Feel free to contact us regarding your specific requirements. We are happy to answer your questions.