Product Swiss Medtech Expo 2019

KKS systems for etching dental implants

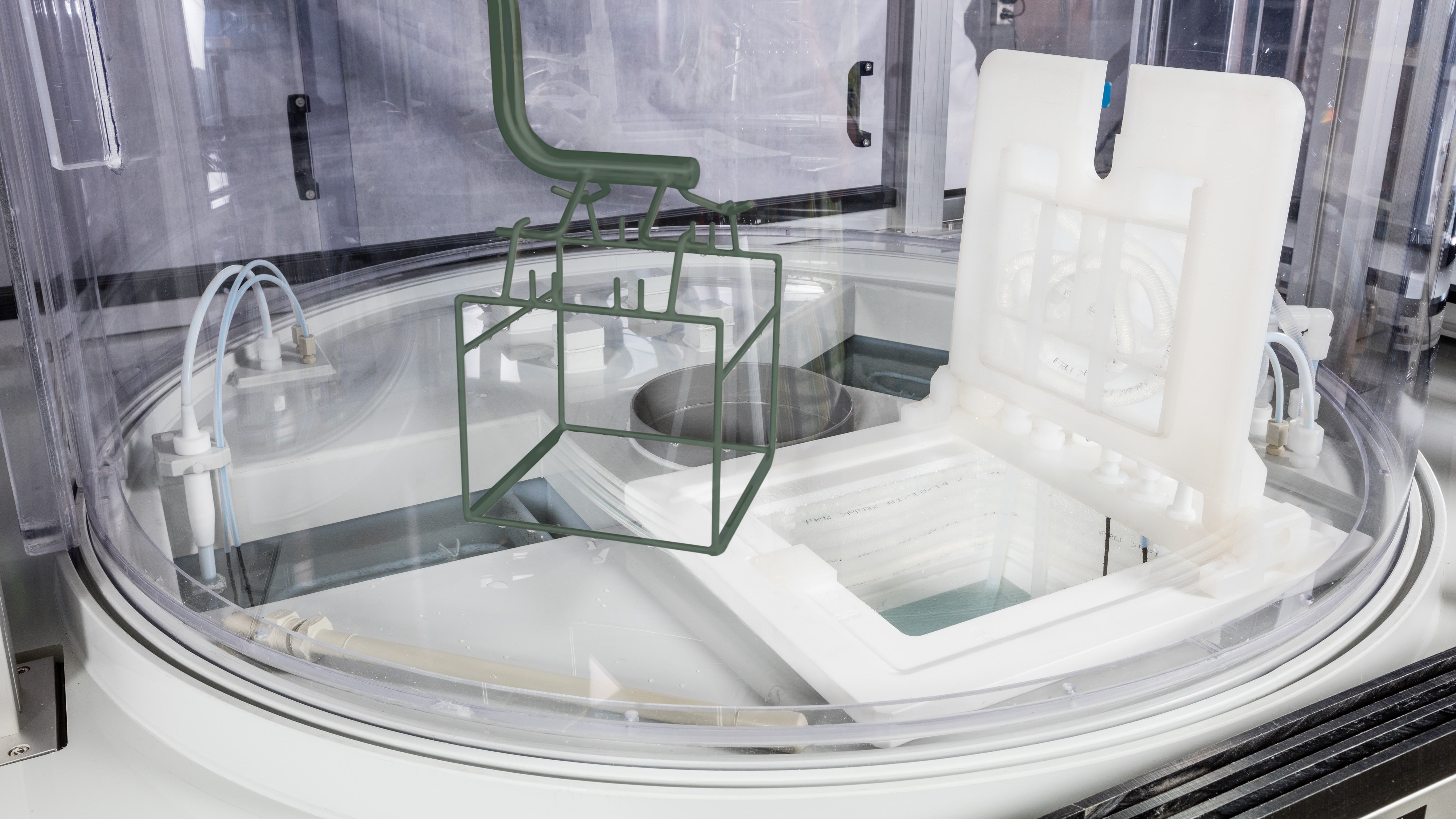

The fully automatic KKS etching systems are specially developed for acid etching of dental implants. The modular design allows the individual combination of different process steps, e.g., pre-cleaning, etching, rinsing and drying.