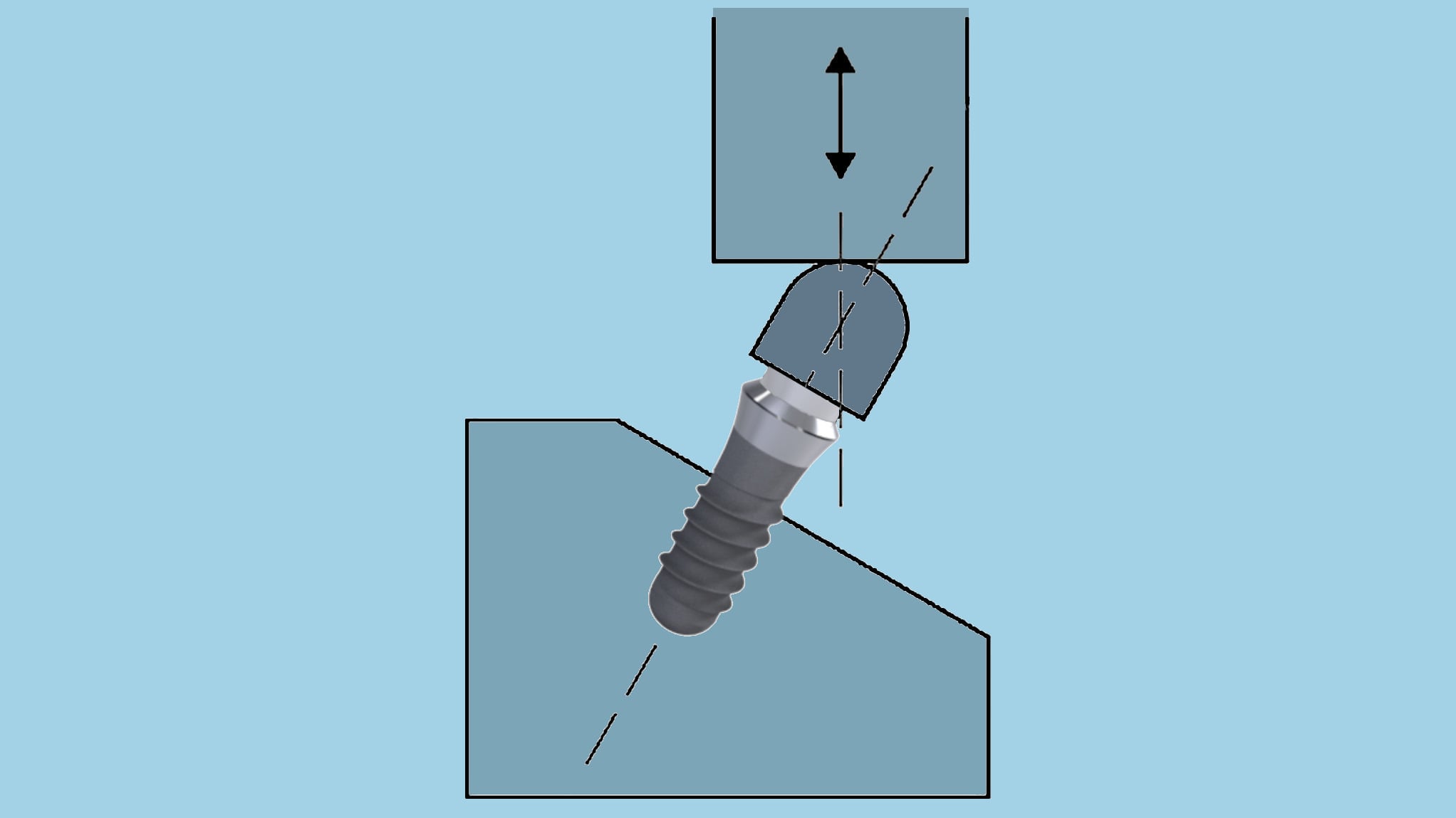

Many medical devices consist of several components and are exposed to cyclical loads during use. Resulting micromovements can generate abrasion particles. To prove the safety of a product, it is often necessary to determine the type, quantity and size of the wear particles.

When medical devices are implanted in a patient, wear particles generated by micro-movements between the individual parts can be released into the body over the period of use. To prove the safety of a product, many medical device manufacturers therefore have the type, quantity and size of the abrasion particles determined, which are formed in a simulated mechanical load situation. Such tests are also increasingly required by the regulatory authorities.

Typical laboratory investigations to determine the particle generation on implants (e.g. dental, orthopaedic or trauma implants) first include a loading test. Here the products are subjected to a cyclical alternating load that is as realistic as possible. The mechanical load is usually applied in physiological test liquid and at body temperature.

During the subsequent particle collection, the highest level of cleanliness must be ensured in order to avoid additional contamination. For this reason, the work is carried out in a clean room. In order to exclude further side effects of the processes, blind and reference samples are always carried along.

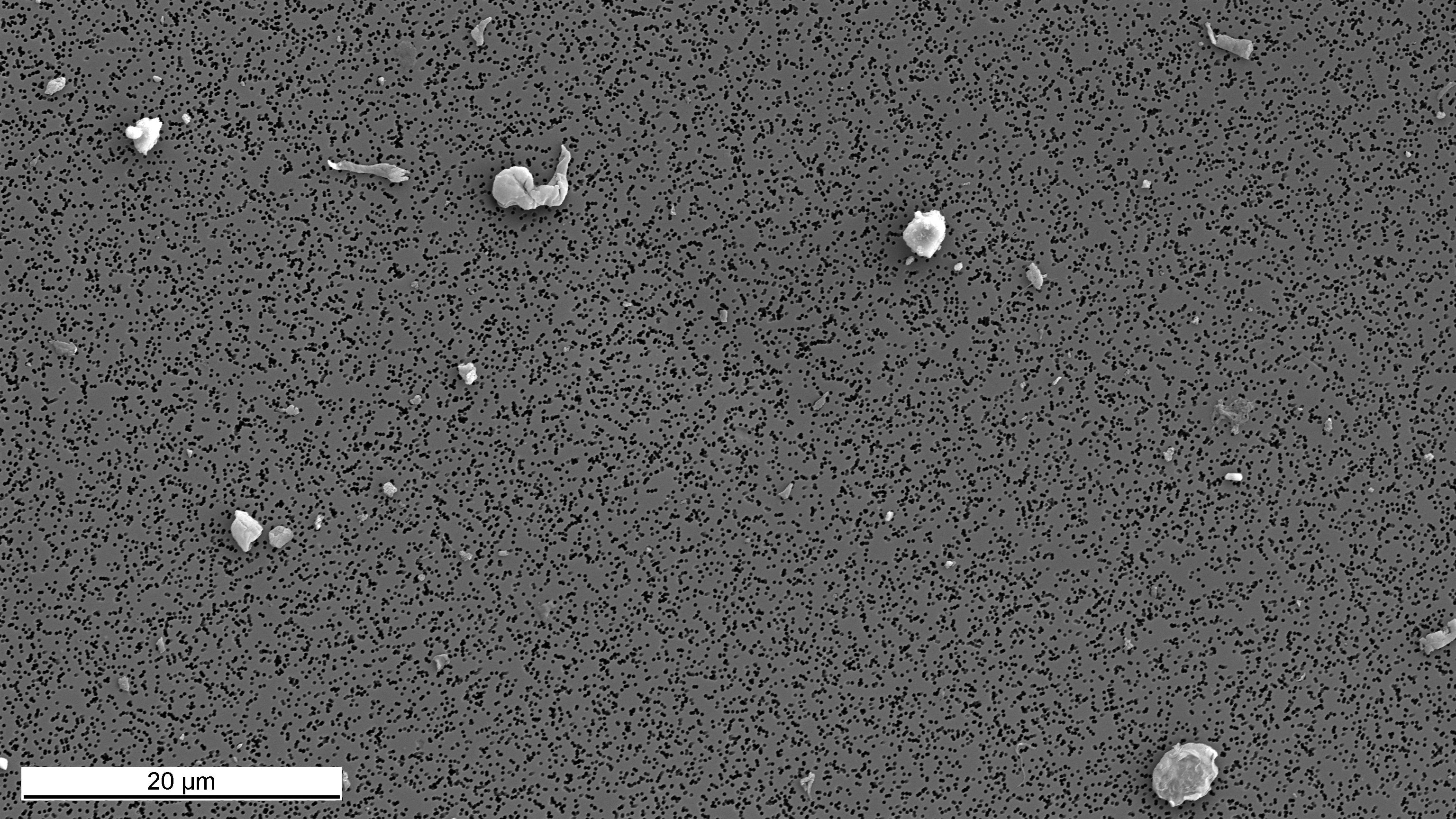

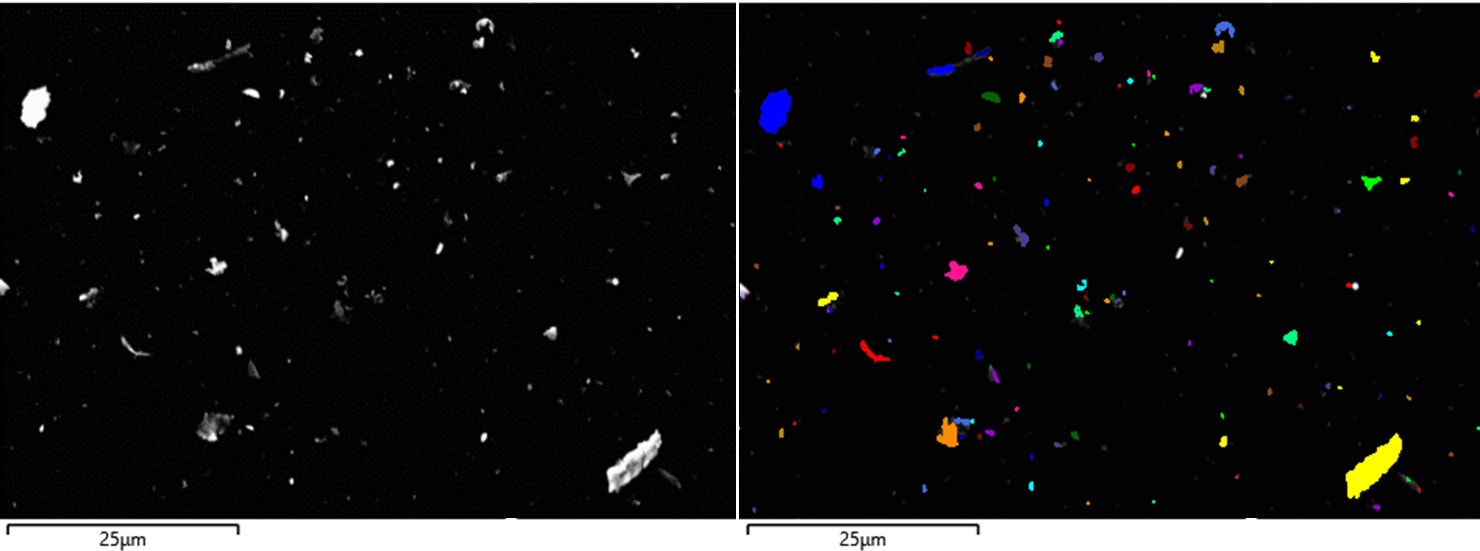

The number and size of the wear particles in liquids can be determined by light obscuration. Particles are collected on filters for a more detailed analysis. The quantity of the generated particles is determined gravimetrically by comparing the mass of the loaded and conditioned filter with that of the filter before the particle loading. The filters are then evaluated by automated light microscopy with regard to the number, size, shape and type of particles. Small particles that are not visible with light microscopes are examined with a scanning electron microscope (SEM). In combination with an EDX analysis or with FT-IR microscopy, the chemical composition can also be determined.

The RMS Foundation has already carried out dynamic load tests with subsequent particle analysis for various manufacturers of implants. The results from these tests served as the basis for evaluating the safety of the medical devices under the selected conditions of use and were used for product registration.

Our possibilities for particle collection and analysis on surfaces of medical devices:

- Implant specific dynamic tests

- Light obscuration AccuSizer A7000 SIS

- Vacuum filtration unit Sartorius

- Analytical balance Mettler XPE 2015

- Filter analysis system Jomesa HFD4

- Scanning electron microscope

Zeiss Sigma 300 VP with EDX-analysis and software AZtecFeature

- FT-IR microscope Bruker Lumos

- ICP-MS Agilent 7700x

Discuss your questions with us! We are happy to advise you.