A consortium of medical technology companies, research institutes and end users set themselves the task of inserting a filter membrane into a multi-part plastic housing without damaging it. Learn how a precise and clean solution could be found with laser welding.

Precise and clean joining of plastic parts

In medical devices, thin membranes are used for many different filtration applications. The filter membranes usually have to be fixed on a carrier or mounted in housing without impairing the functionality of the membrane.

A consortium of medical technology companies, research institutes, and end-users was facing this task within the framework of an EU project.

Adhesive bonding of the membrane was not desired because of the materials involved, concerns that adhesive could flow into the membrane and the possible contact of the adhesive to the liquid to be filtered.

With ultrasonic welding, the danger of damaging the membrane with the mechanical vibrations was too large. In addition, a rib must be melted down during ultrasonic welding, which can lead to contamination by particles.

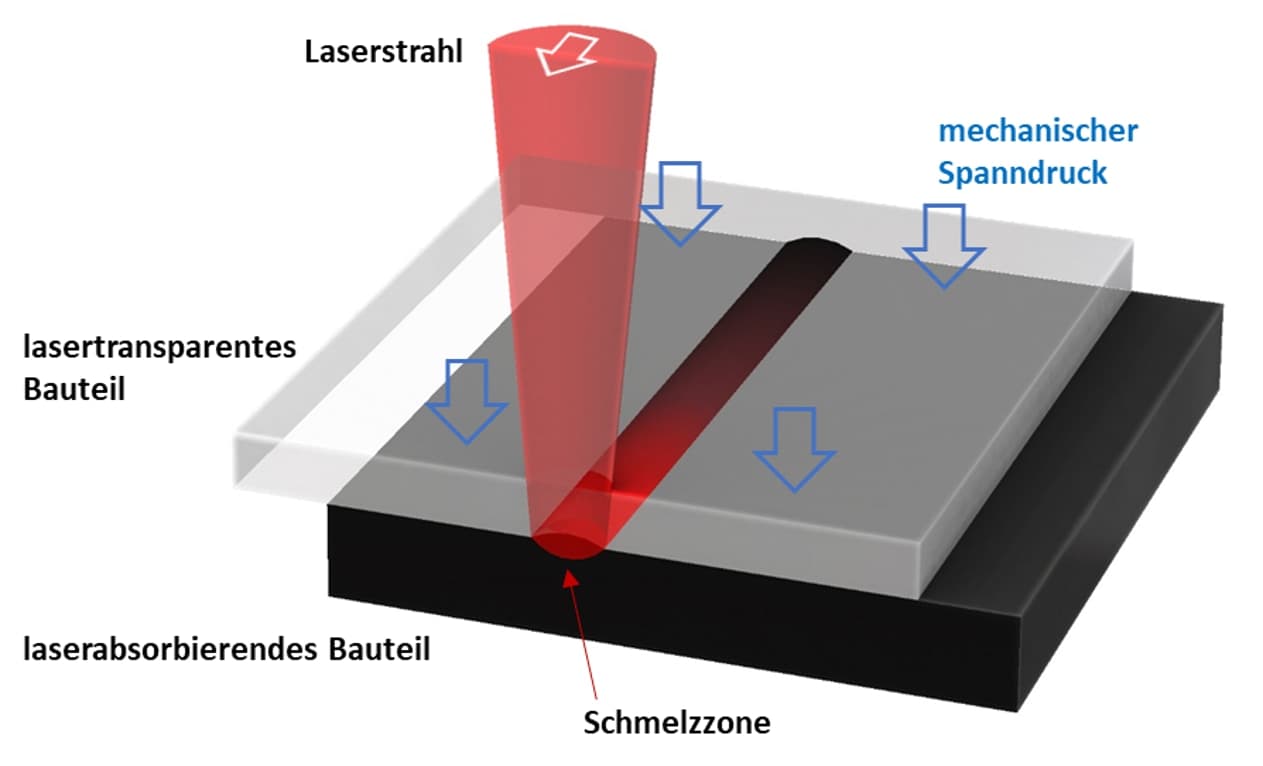

With laser welding, a solution could be found to weld all 4 plastic parts of the assembly leak-tight together and the fix the filter membrane without any damage.

Approach

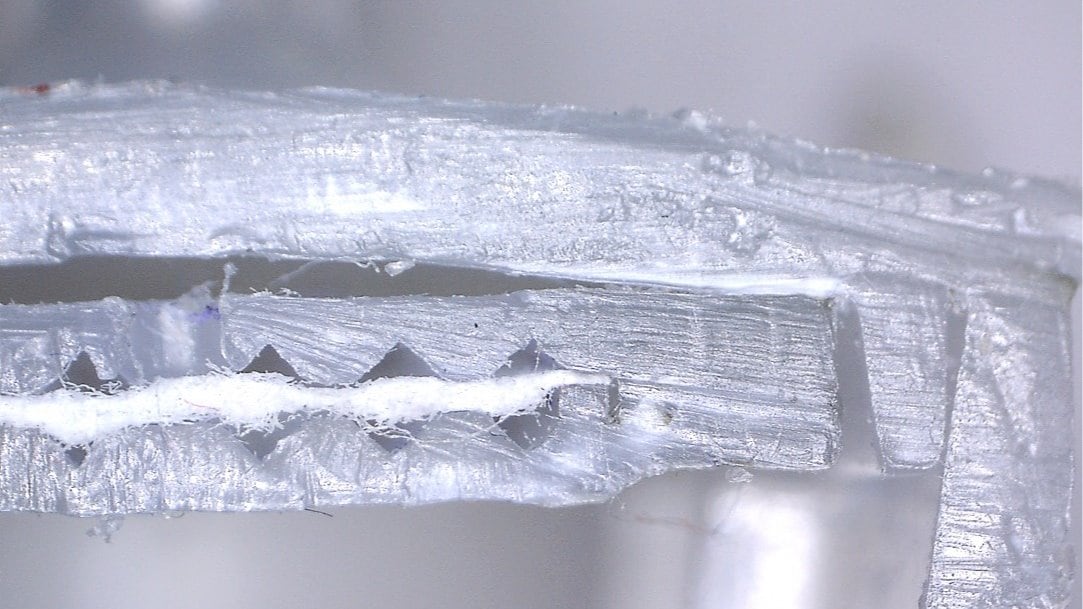

In the first step, the filter membrane is inserted between the filter holder plates. The structures in the filter holder plates allow the liquid to be evenly distributed and to mechanically clamp the membrane between the holder plates, which are then sealed during the welding process.

In a second step, the previously joint filter plates are welded leak-tight into the cover lid with the liquid inlet so that no liquid can flow around the filter membrane.

In the third and final step, the cover lid with filter plates is welded onto the housing, whereby again a leak-tight and firm connection must be achieved.

For first functional samples, the plastic parts have not been specifically colored for the laser, but a laser-absorbing dye has been applied manually to the filter holders and the housing. For the later prototypes, the filter holder plate 1 and the housing are colored for laser welding by a visibly transparent, slightly bluish colorant that absorbs the laser well and is compatible with medical requirements.