Product Swiss Medtech Expo 2021

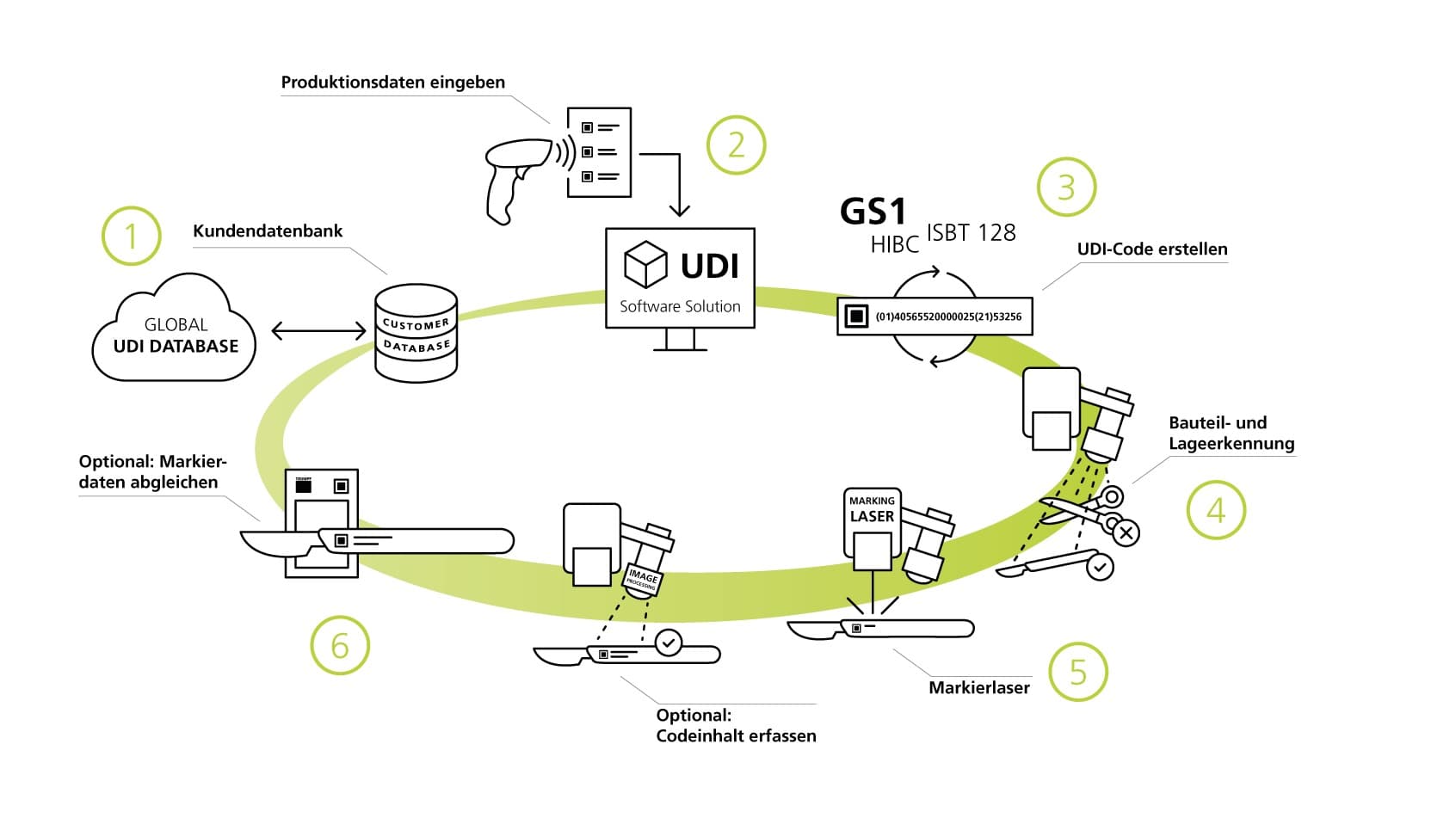

UDI-compliant Laser Marking

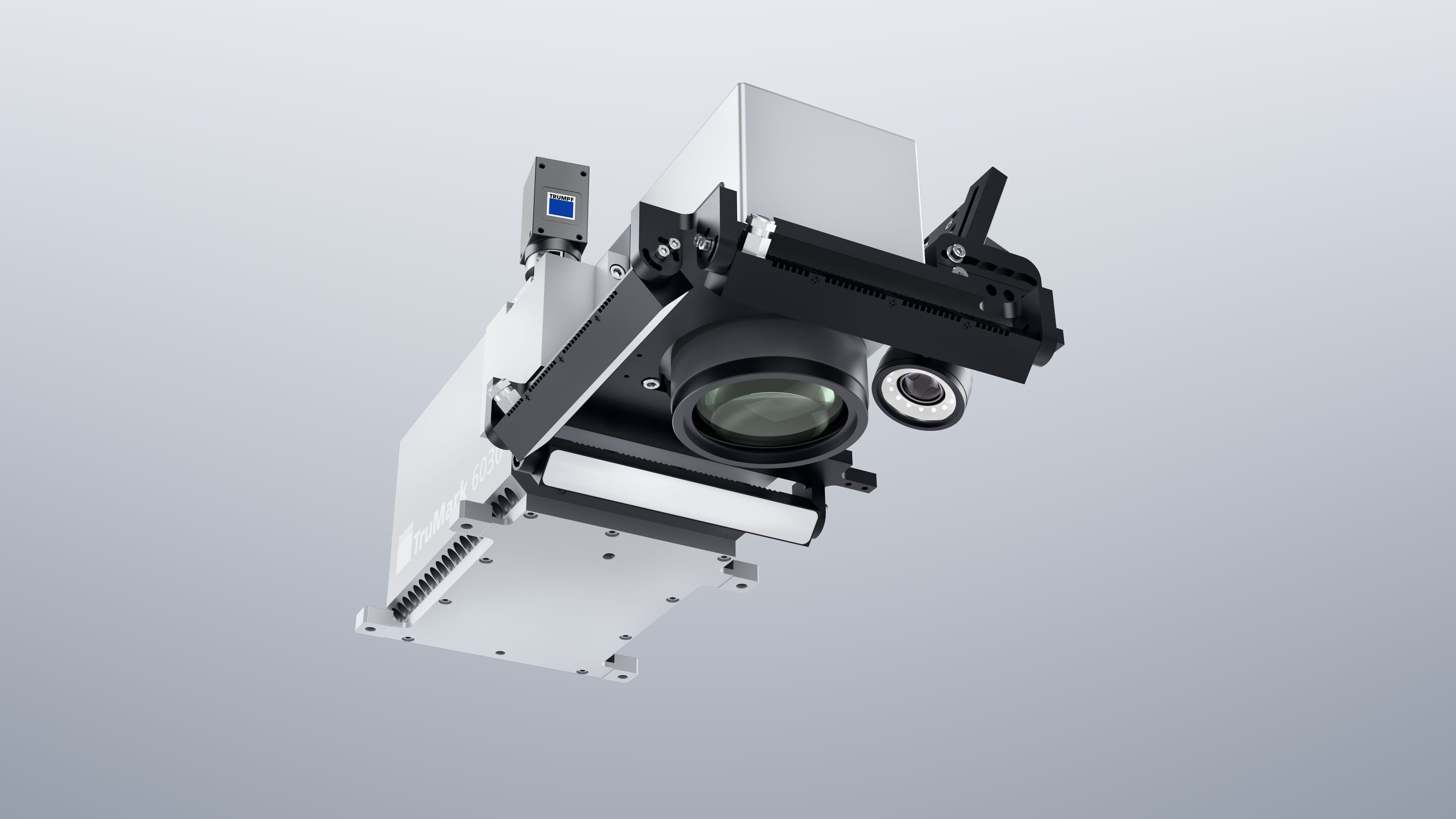

The VisionLine image processing software delivers high process reliability and increased productivity using automatic position recognition. Time-consuming setup, expensive fixtures and unnecessary rejects are a thing of the past.