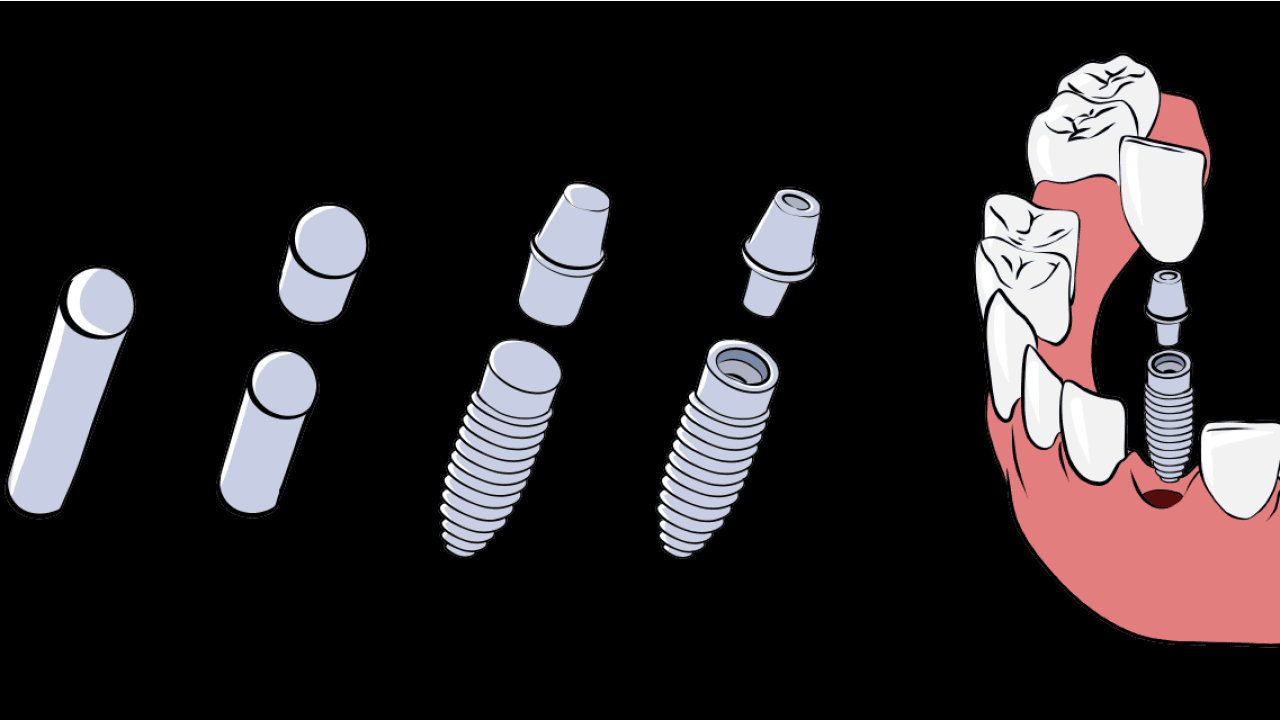

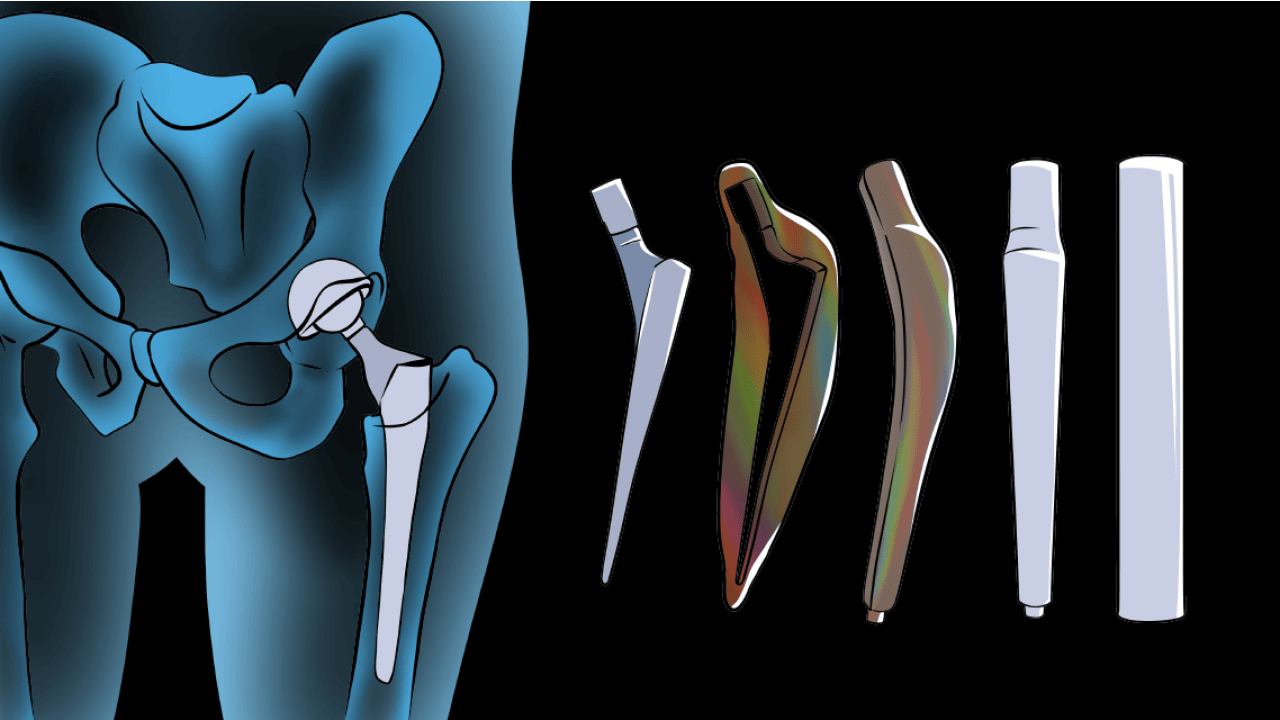

Titanium bars are often processed in sizes larger than necessary due to standard dimensions' availability. However, using custom-sized bars can be more efficient and cost-effective. Are you sure you are processing the right diameter?

Could your machine run better with taylor-made diameters in tolerances up to h6? Every millimeter reduction in diameter leads to square savings.

-

Less material waste: Using bars closer to the final size results in reduced material removal during machining, minimizing waste.

-

Faster processing times: Using bars near the desired size can shorten machining times, leading to quicker turnaround and potential cost savings.

-

Reduced stresses/warpage: Custom-sized bars closer to the final dimensions introduce fewer stresses, resulting in better quality with fewer defects.

Custom machining of titanium bars can save time, reduce costs, and produce a higher quality product with less waste. We offer personalized consultations, attractive minimum quantities, fast delivery times, and tight tolerances up to h6.

https://hartmann-materials.ch/

HARTMANN MATERIALS AG Supporting your Success