GC Aesthetics ™ contacted KEYENCE to purchase a new digital microscope. The new KEYENCE system offers high-resolution images and easy operation of multiple metrology parameters.

Over the years KEYENCE has become a global leader in the development of measurement and quality assurance solutions. The company’s extensive line card includes sensing, vision and measurement products, along with laser markers and microscopes. KEYENCE is continuously looking to develop innovative and reliable products to meet the needs of its large customer base. These products and solutions are making their mark in every market sector, all over the world.

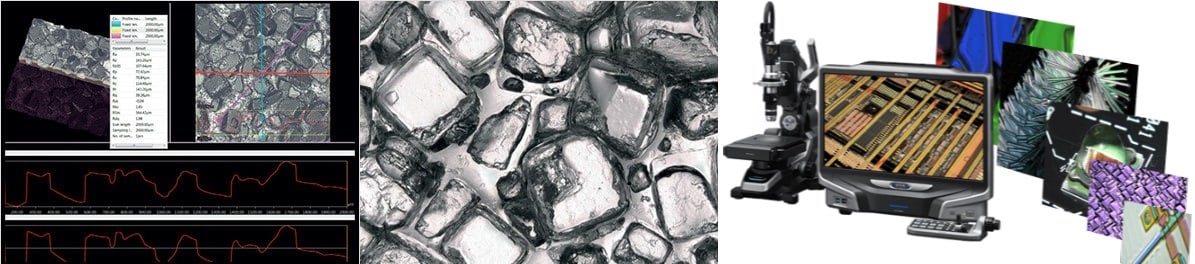

It was no surprise, therefore, to see medical aesthetics specialist GC Aesthetics™ turn to KEYENCE when the time came to acquire a new digital microscope. During the course of its business activities, there are many technical requirements that need to be assessed, investigated, measured and controlled by GC Aesthetics™. One particular requirement is that of surface finish on implants to assess various metrology parameters and surface topography features, patterns, consistency, and uniformity.

“GC Aesthetics™ has more than three decades of experience manufacturing silicone implants through its brands Nagor® and Eurosilicone®” explains Fraser Harvie, Product Development Manager. “We work in partnership with the medical community to continually develop high-quality products and services that meet both the surgeons’ and patient’s clinical needs.”

GC Aesthetics ™ has outsourced techniques such as scanning electron microscopy-REM and digital microscopy. According to Harvie, the turnaround time for the results of outsourcing such tests was sometimes time-consuming. To minimize time and change implementation, the GC Aesthetics technical team took it for granted to consider as wide a range of measurement products as possible.

When asked about the buying process, Mr. Harvie said: “We had a clear understanding as to what was needed to maintain the highest standards of measurement, quality, and safety. The technical team whilst not having used a KEYENCE product before, all felt the need for a system that could generate imaging of the highest resolution.”

In addition to quality imaging, the chosen device needed to be small and indeed portable enough to be moved easily if required. Lastly, operating multiple metrology parameters had to be a simple enough affair: and the KEYENCE system delivers such information at the click of a button…or two!