Product Swiss Medtech Expo 2023

RFIM Measuring Unit

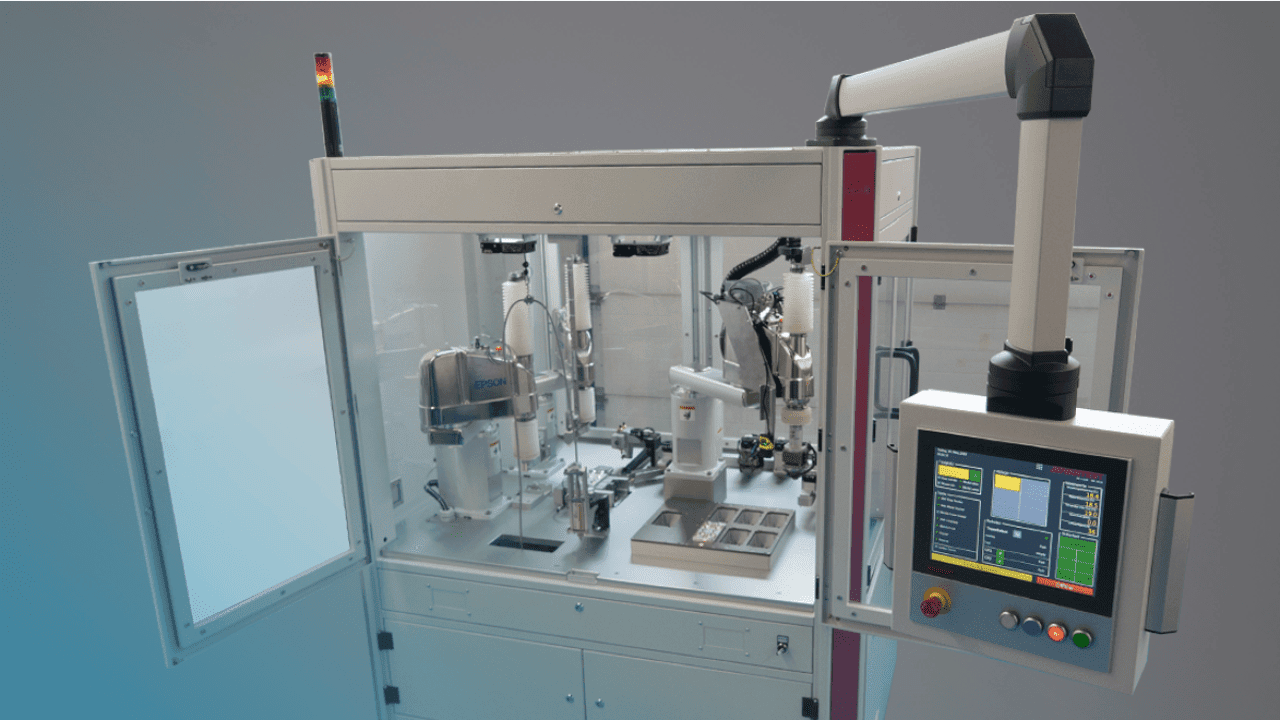

Fully automated characterization of RFIMs (Radio Frequency Interface Modules). DMTpe develops, builds and supplies RFIM measuring units for RFIM production lines as a development service provider and manufacturer.