When determining the mechanical seal strength according to ASTM F2824, the force required to pull off the blister lid at exactly 45° is determined. The results serve for quality assurance of the packaging and help to assess the uniformity of the sealing seam.

The RMS Foundation offers various test methods for characterizing the packaging of implants, instruments and sterile packaged consumer goods. Typical examples of container shapes are oval, rectangular and round trays, with single or multiple cavities and with a sealed lid.

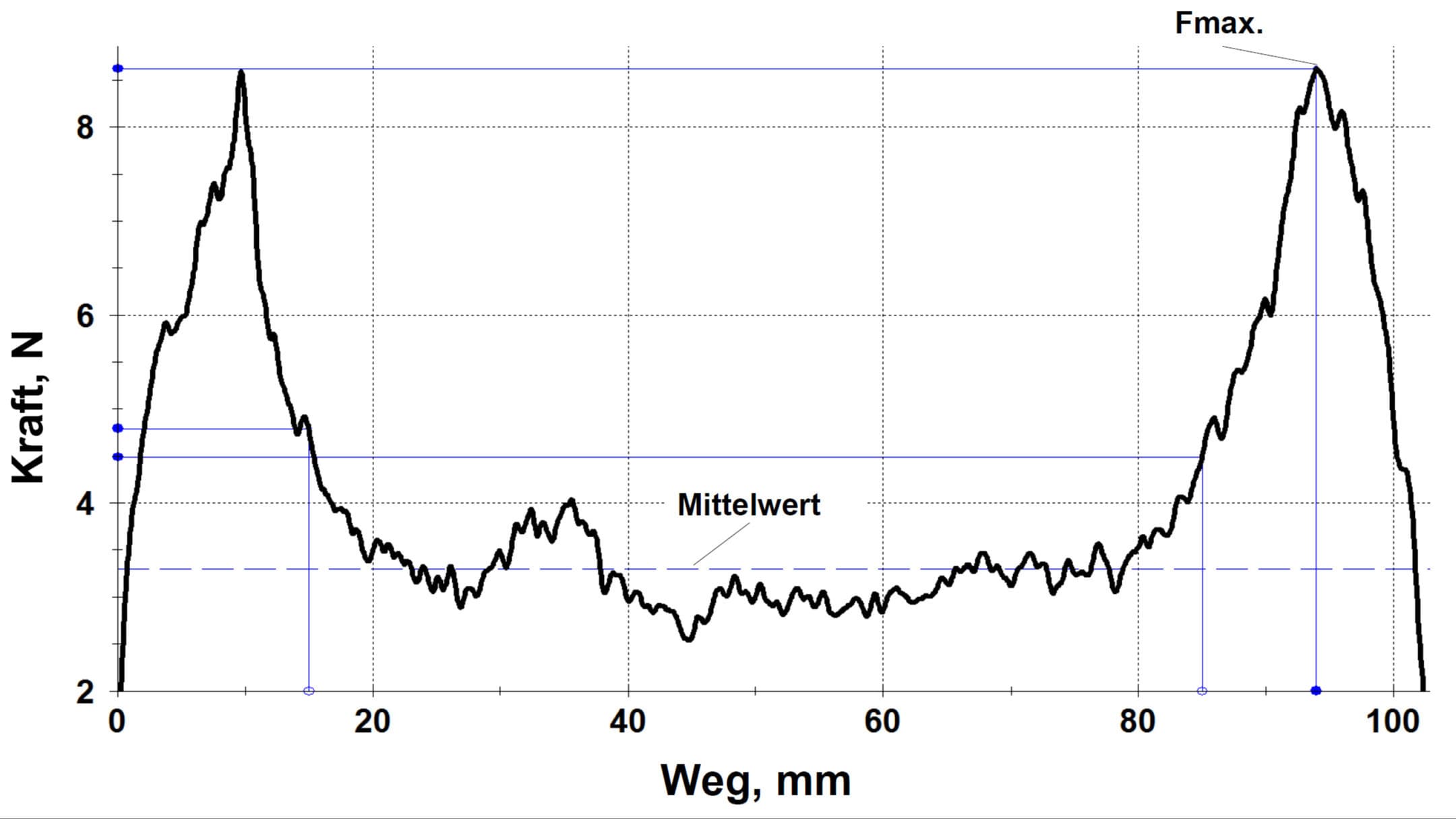

During the test, the sample (container) to be tested is securely fixed to the test setup. The lid is pulled off at a constant angle of 45° over the entire test period. This is made possible by horizontal movement of the blister. The starting point when removing the lid is the tear tab. This is fastened on top in the gripper with load cell. The lid is then removed from the container at a constant speed along the sealing seam of the container. The forces measured during the test are recorded and can be used graphically and numerically for the test report.

When determining the mechanical seal strength when detaching the entire lid (lid / membrane) from a rigid or semi-rigid container (blister) according to ASTM F2824 or ASTM F88, both the continuous and the maximum force required to pull off the lid is determined. The mean value over the entire curve or over the "valley to valley" area as well as the work performed are also evaluated.

The knowledge gained can be used for the overall evaluation of the uniformity of the sealed seam and thus for quality assurance of the packaging.