Additive Manufacturing (AM) in a certified environment according to DIN SPEC 17071 (later ISO ASTM 52920) and controlled conditions (clean room ISO 8 in operation) from the idea to the prototype to the sterile packaged medical product or implant.

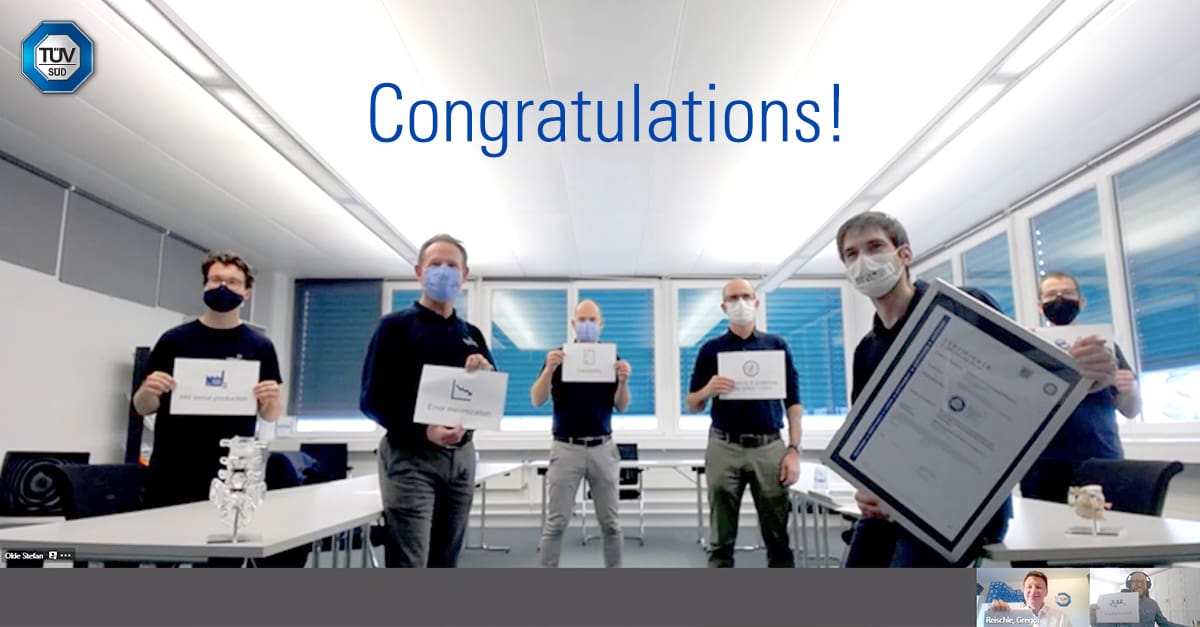

SAMAPLAST AG has been certified in accordance with DIN SPEC 17071 for additive manufacturing (AM) since November 2020 and/or in accordance with ISO ASTM 52920 during the course of 2021.

With this AM certification, SAMAPLAST AG fulfils the following TÜV SÜD inspection criteria for third parties:

- Quality management for AM processes

- Service competence for consulting and production

- Quality assurance for industrial and medical applications

- Reproducible and traceable processes

- Controlled material qualification/validation

- DIN SPEC 17071 implemented

With this AM certification and EN ISO 13485 and/or registrations and permits, from the FDA, ANVISA and JPAL, SAMAPLAST is in a position to fulfil the critical requirements and crunch points in AM manufacturing for the medical technology/implant market.

Manufacturing from the initial idea to packaged medical product or implant made from high-end plastics such as PLA, PEEK, TPU and PCU in a controlled environment (ISO 8 in operation), on qualified 3D printers and freeformers, and in a holistically functional, valid environment/system built on a risk-based approach can be implemented smoothly together with the customer.