The need for marking of medical devices leads to questions about their resistance. For a manufacturer of orthopaedic implants, RMS tested the corrosion resistance of laser markings with the EC-Pen, which enabled the resistance of medical products to be specifically optimized.

Part specific coding required

According to the new European Medical Device Regulation (MDR), many medical devices must be identified by part-specific coding (UDI codes, Unique Device Identification). For this purpose, laser markings are used today for metallic products. The products must carry the UDI identifier in two forms: in easily legible plain text (HRI/Human Readable Interpretation) and in AIDC format (Automatic Identification and Data Capture), i.e. as machine-readable identification (barcode or 2D code). The data for each individually marked product must then be stored in a central database (e.g. European Database for Medical Devices, EUDAMED).

Deterioration of corrosion resistance

Laser marking represents a change in the surface and can therefore also mean a deterioration in corrosion resistance. Depending on the base material, a corrosion attack by pitting is preferably found at the marked areas. Particularly with cutting instruments, a compromise between hardness and corrosion resistance often has to be made when selecting materials and heat treatment. This can lead to instruments not being sufficiently passive on the laser markings and subsequently corrosive attack during cleaning and reprocessing in contact with the aggressive environment.

Practical experience shows that not only the selected material (steel grade) and the heat treatment have an influence on the resistance, but also the laser parameters applied during marking and the downstream processes (passivation, electropolishing) are decisive. As a result, the corrosion resistance of laser markings should always be checked.

Corrosion measurements with the EC-Pen

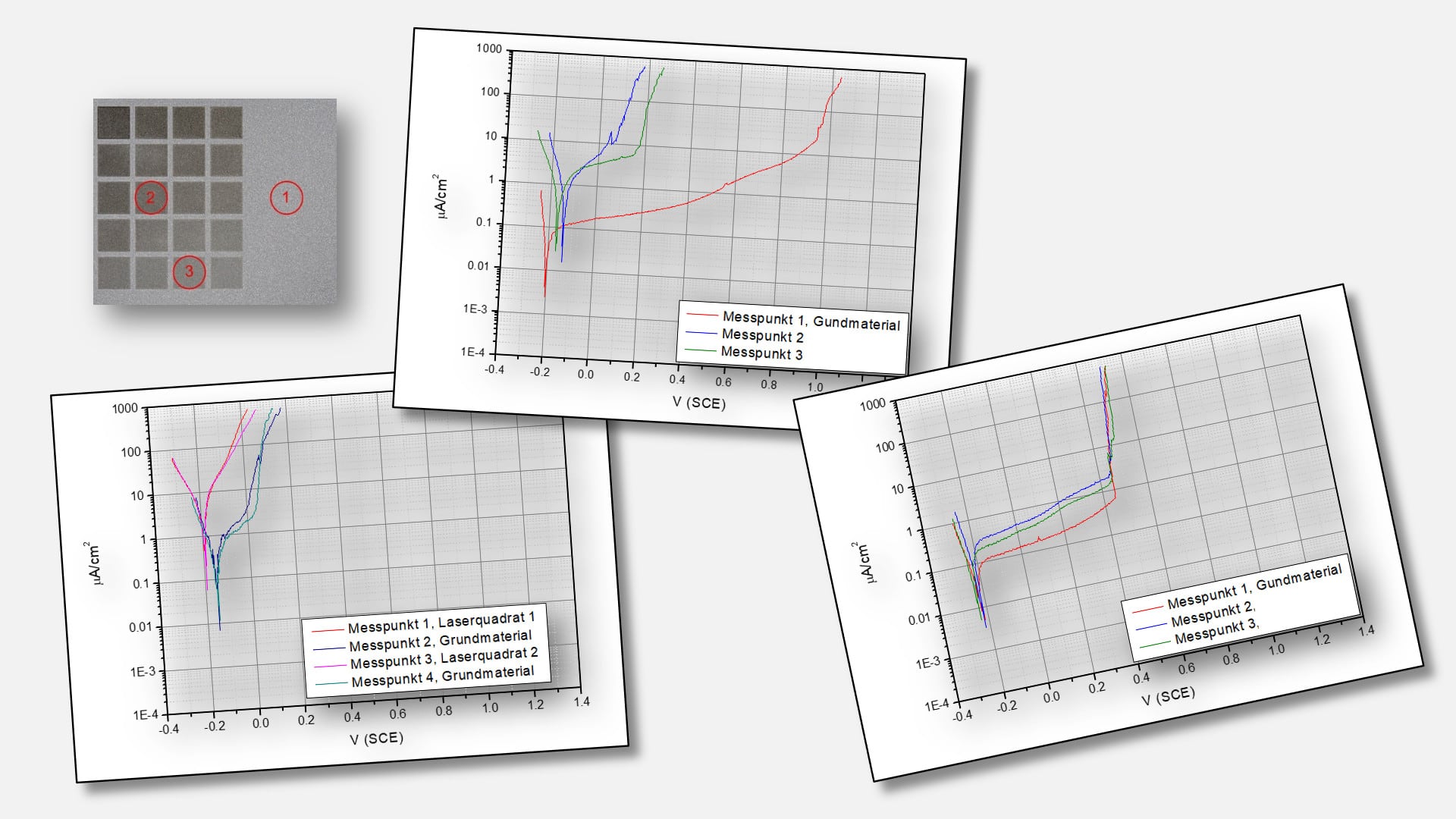

In a current customer project for a European manufacturer of orthopaedic implants, the corrosion resistance of laser markings on the corresponding instruments was investigated. The RMS Foundation has a local electrochemical test method available for this purpose. The system known as "EC-Pen" consists of a pen-like probe that is placed directly on the surface. The pen is filled with an electrolyte (e.g. physiological NaCl solution) and contains the electrodes required for the measurement. The local corrosion resistance is measured at the contact point, which is only approx. 1.5 mm2. The result is a current density versus potential curve, which indicates whether the part is passive (resistant) or active (sensitive to corrosion) at this point. The influence of the marking can be determined by local measurement on laser tracks and comparison with measurements on the unlabelled base material. This does not require any specific sample preparation which could influence the results.

With this method, the corrosion resistance of laser markings with different process parameters was investigated and compared in the customer project described above. This made it possible to optimize the passivity and durability of medical products in a targeted and step-by-step manner. The corrosion measurements with the EC-Pen also have the advantage that they represent a rapid and thus comparatively inexpensive measuring method.